Precision Component Manufacturing with CNC Machining

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Norck: Your Partner for Precision Insert Molding Solutions

Norck delivers expert insert molding services, empowering manufacturers across aerospace, automotive, medical, electronics, and other demanding sectors to create complex, multi-functional plastic components.

Capabilities for Insert Molding Excellence:

Norck's Engineering Edge: It's About Integration, Not Just Encapsulation

Why Choose Norck for Insert Molding?

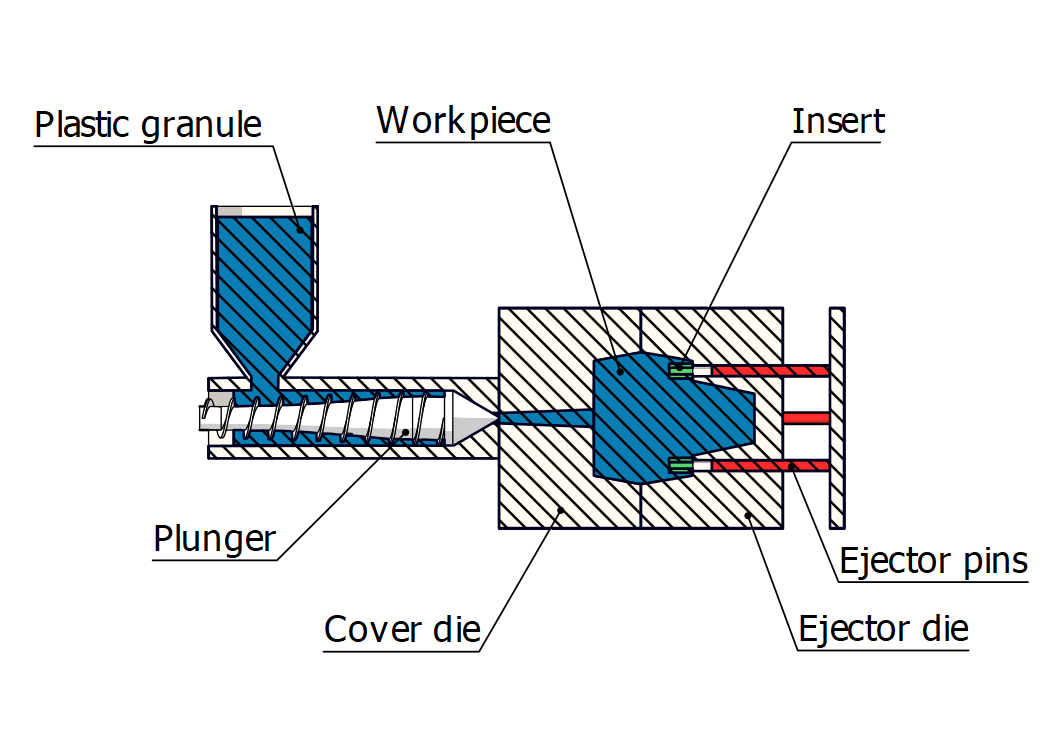

It is a plastic injection molding process that combines plastic and other material. The insert, the inner part of an over-molded component, is inserted into the mold before injecting the plastic material. The mold is made from hardened steel to withstand the pressure and heat of the insert molding process. The Insert molding process is used for high and medium-volume production due to the high cost of mold fabrication.

Insert molding is used to add the insert, such as:

• A threaded insert, a metallic part similar to a nut to add a rigid thread to a plastic part

• Electrical pins and connectors

• Screws

• Keys

• Gears

Insert molding offers many advantages:

• A rigid connection: The injected plastic englobes the insert, which results in a rigid connection between materials.

• Accuracy: Insert molding offers tight tolerances, around ±0.05mm.

• More rigid threads: The inserts are added to a plastic part to avoid wearing of threads in plastic material.

• Diversity of materials and colors: Many materials can be used to make Insert molding and a large selection of colors.

• No finishing is required: There is no need for post-molding operations as the molded parts come off the mold and can have a mirror glass surface, mat color, or texture.

• Low production costs: The production cost is reduced since post-machining operations are reduced or eliminated.

But there are some disadvantages as well:

- Complex tooling design

- Long cycle time

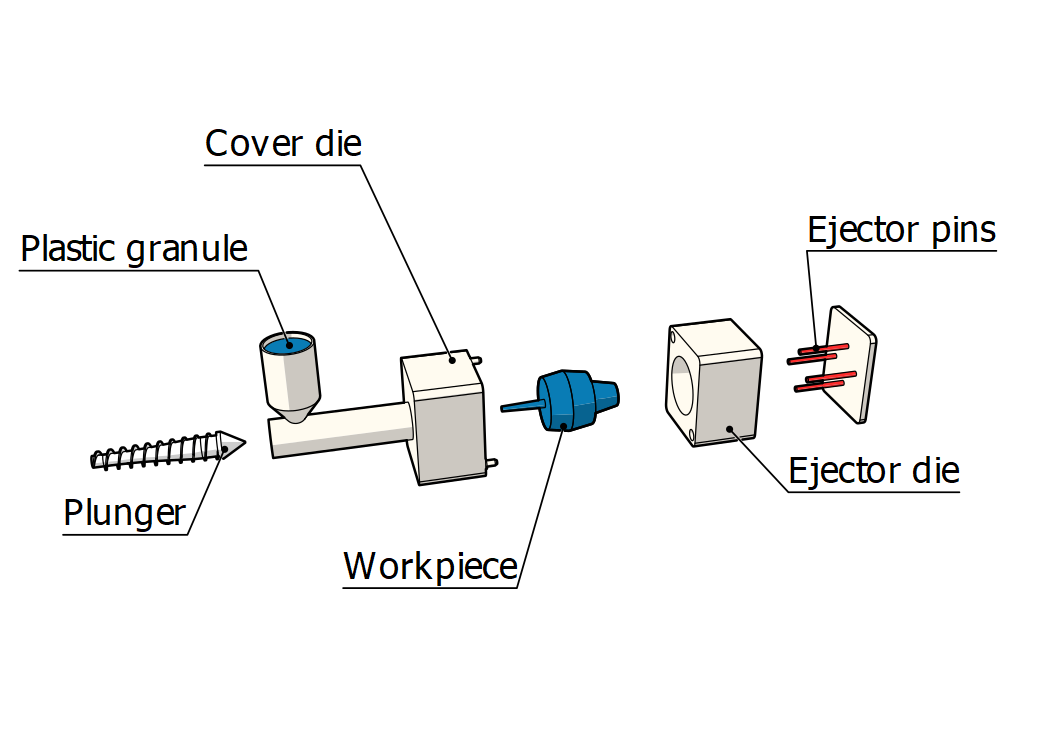

Insert molding is made through four steps:

1. Plastification and adding inserts: The plastic granules are transferred from the hopper to the mold using a rotating screw and molted using heaters. Inserts are added before the injection manually for low to medium-volume production or automatically for high-volume production.

2. Injection: The screw will advance to increase pressure in the injection chamber to inject the molted plastic into the mold. The two cavities are maintained close until the plastic solidifies

3. Cooling: After injection, the molted plastic will be cooled down to become solid using a cooling circuit. The screw will hold its position to hold the pressure inside the mold.

4. Ejection: After the molted plastic solidifies using a cooling circuit, the Die is opened, and the part is ejected via ejector pins. The screws will retreat to prepare for the next injection.

Obtaining a fully functional part might require extra processing for features that can’t be made with the Injection molding process, such as taping. The designed part should follow Injection molding design guidelines.

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.