Precision Component Manufacturing with CNC Machining

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Norck: Your Source for High-Precision CNC Grinding

Norck delivers expert CNC grinding services optimized for exceptional surface finish, tight tolerances, and demanding applications across aerospace, defense, robotics, industrial, automotive, electronics, energy, hardware, and consumer products.

Capabilities:

Why Norck for CNC Grinding?

CNC grinding (Computer Numerical Controlled grinding) designates a process where an abrasive wheel refines a workpiece by removing small amounts of material. Grinding is made after machining to remove micro inches.

CNC grinding offers more advantages over traditional grinding methods:

• Higher accuracy: CNC grinding offers tight tolerances that can reach ±1µin (±0.025µm).

• More consistent: It is a more consistent process since it is controlled via a computer.

• Higher surface finish: CNC grinding offers smoother surfaces that can reach Ra 2µin 0.05µm

There are several types of CNC grinding, such as:

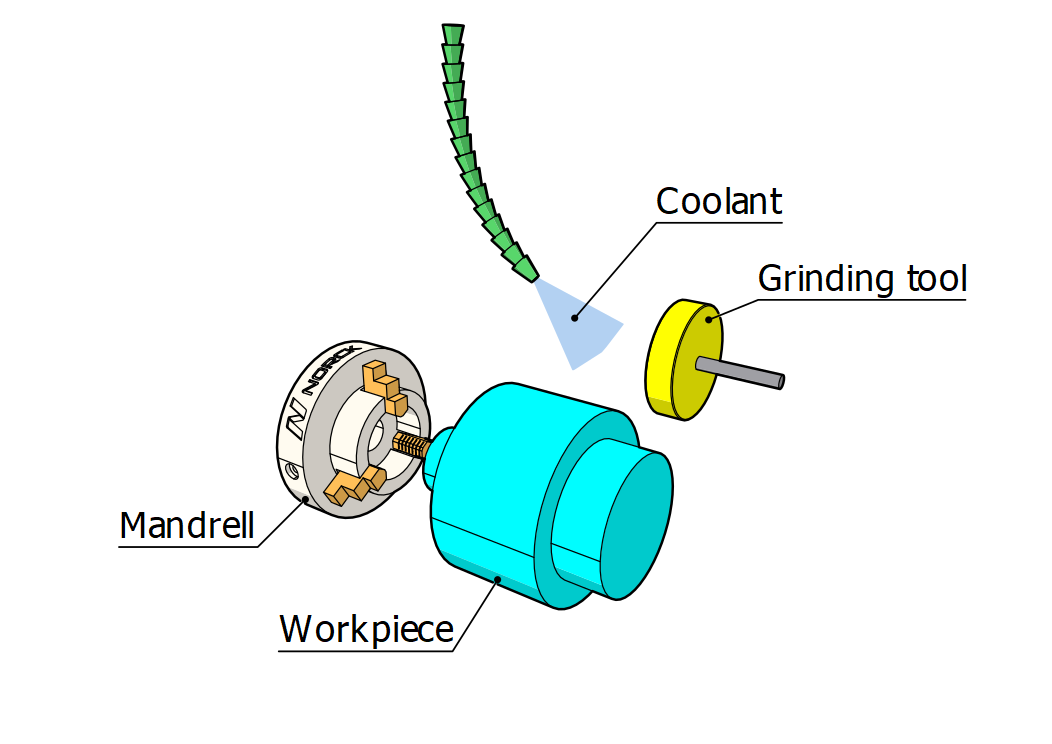

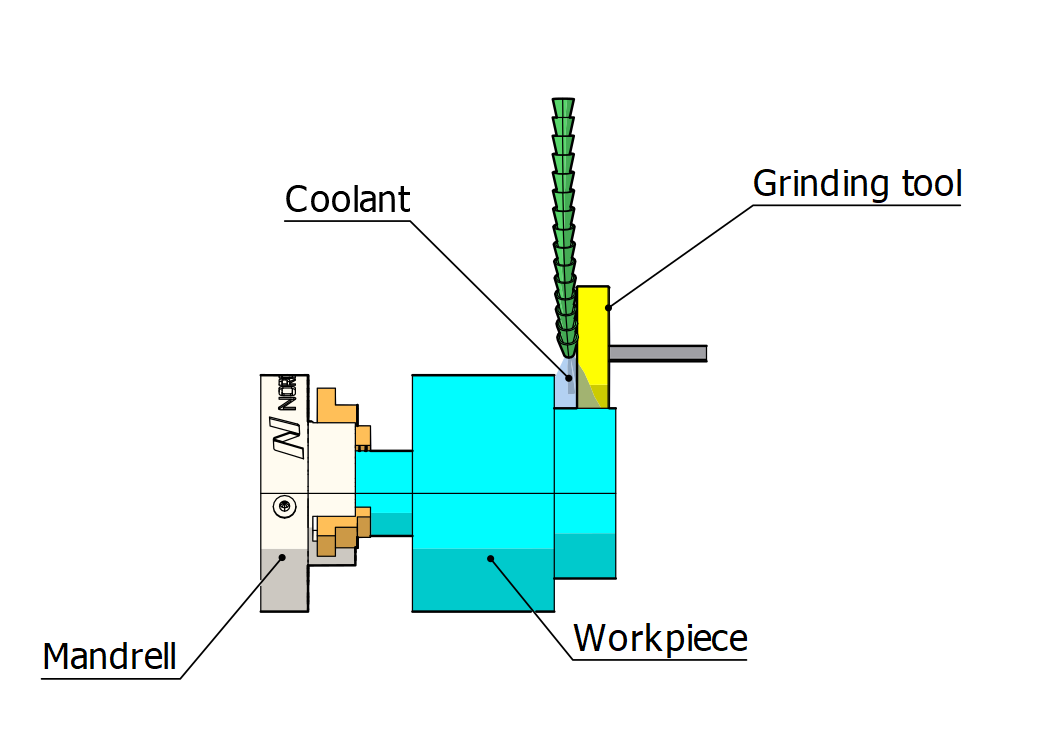

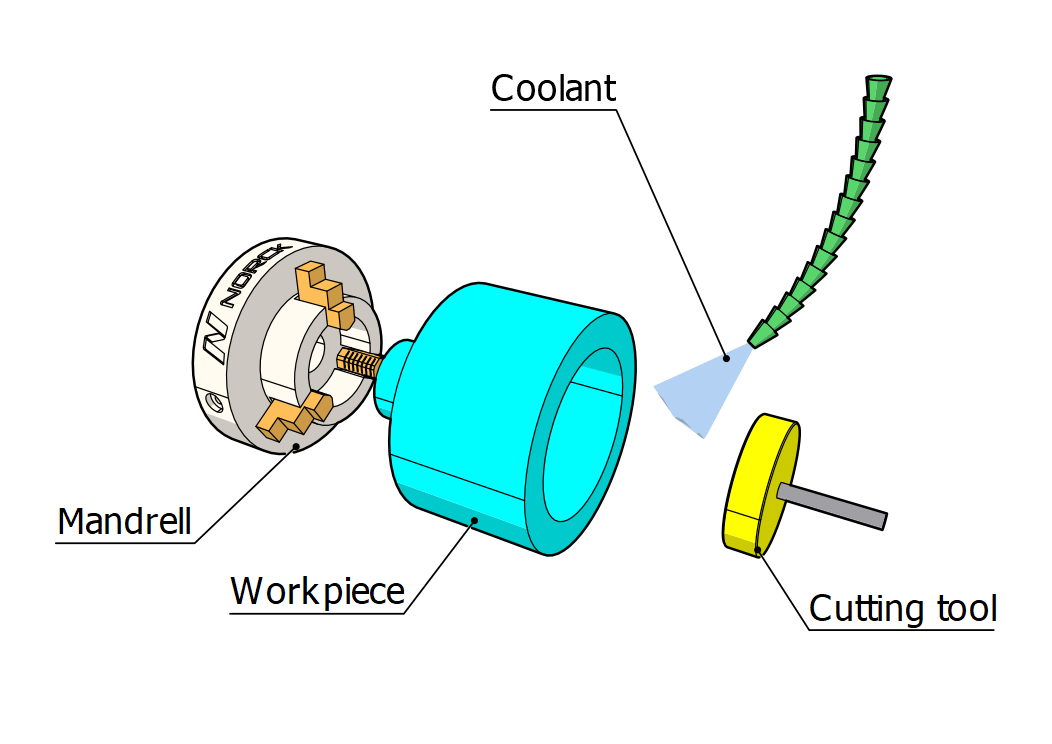

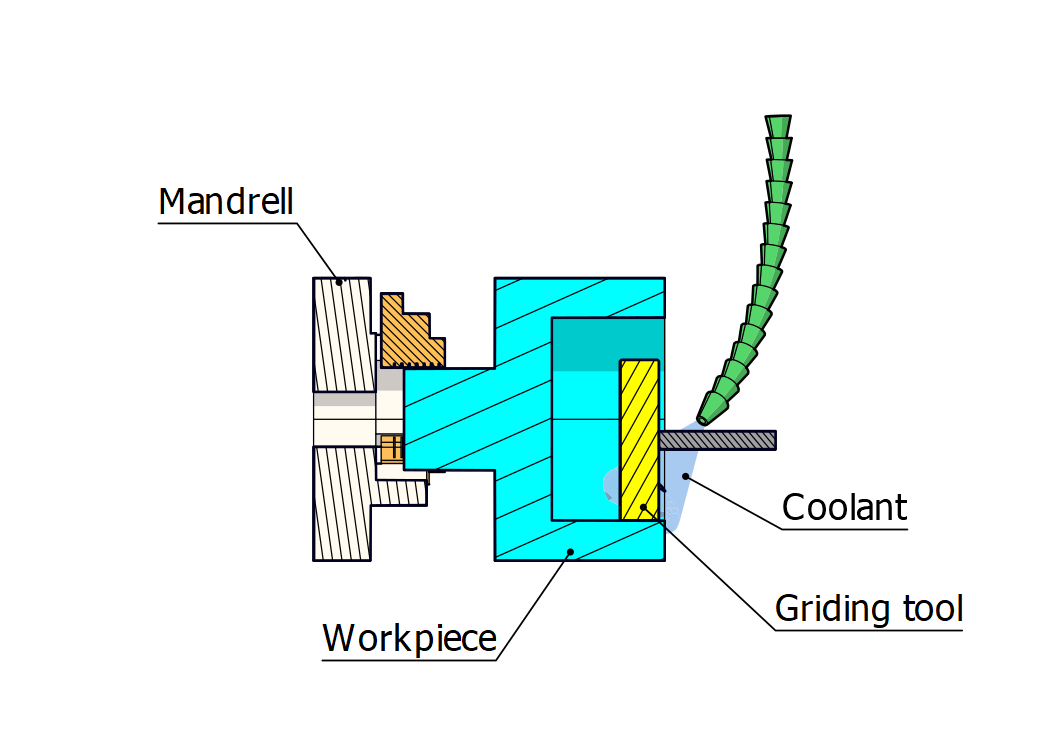

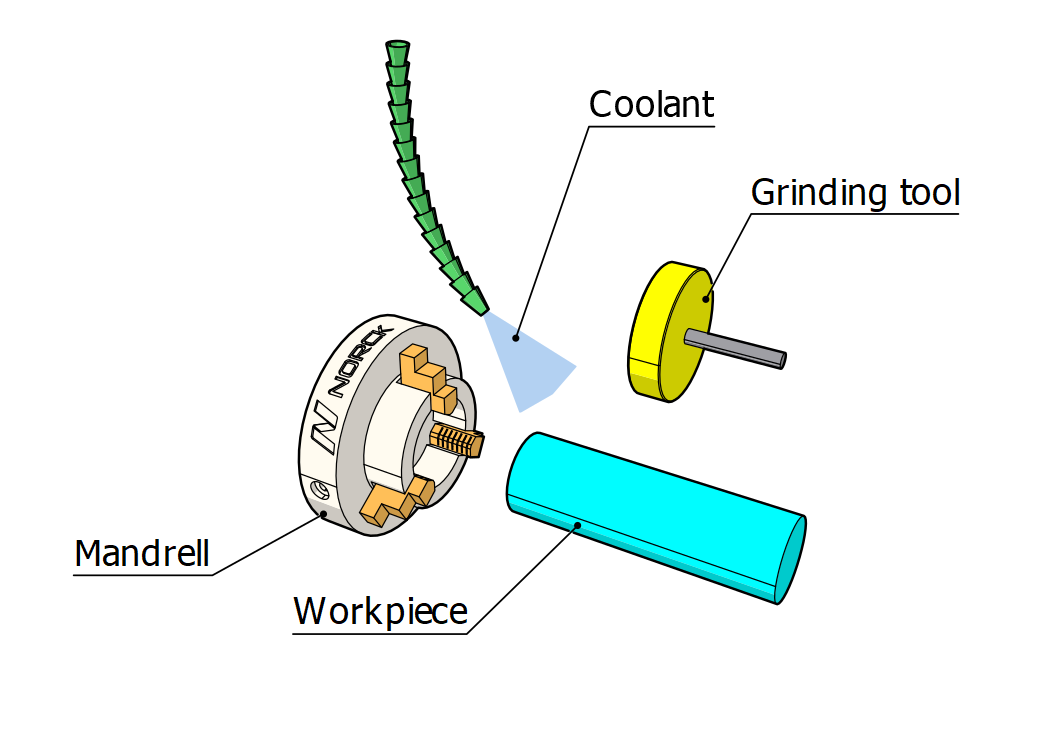

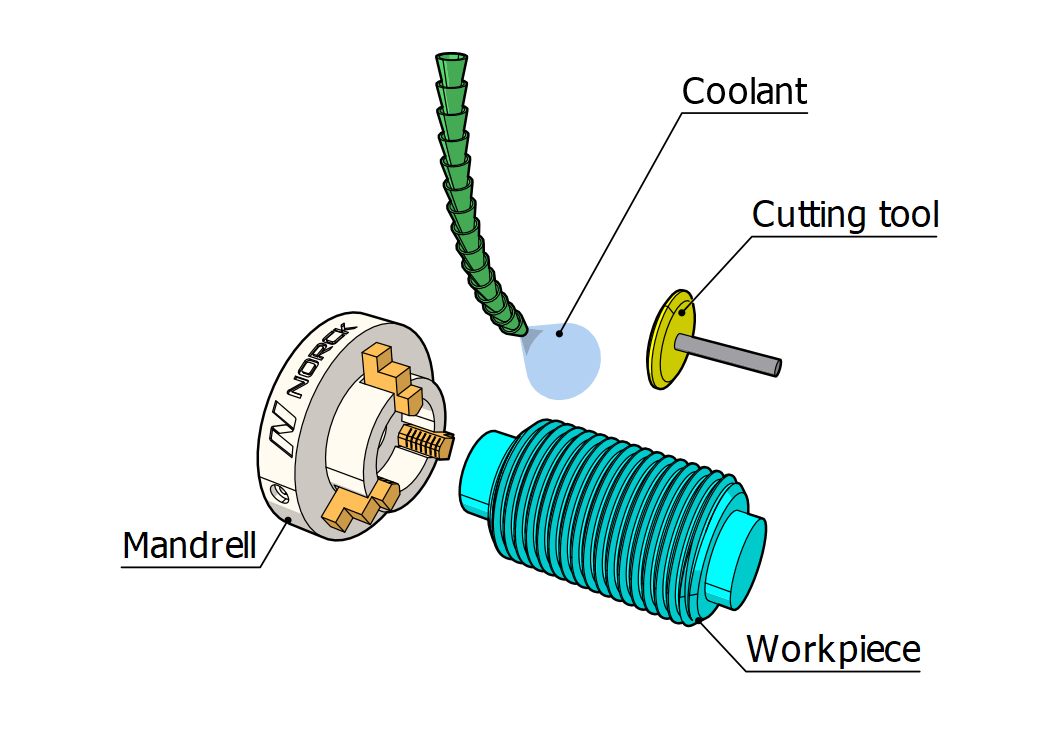

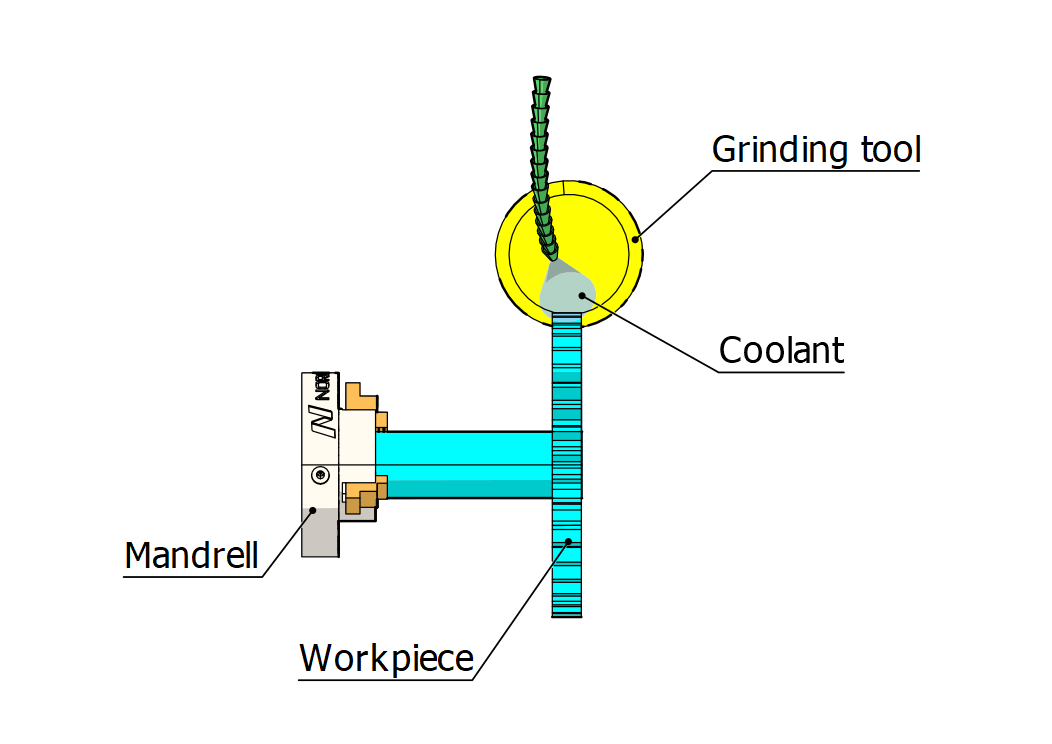

1. Revolving parts : In this process, the workpiece is held in a mandrel and it rotates at high speed. A grinding wheel is then used to remove a thin layer of material while the part is in high rotation. A coolant supply is constantly poured onto the grinding wheel to cool it down. CNC grinding can be used for cylindrical parts, whether centric such as shafts, cylinders, and disks, or eccentric parts, such as crankshafts and camshafts.

Cylindrical grinding can be made for a cylinder's internal and external surfaces.

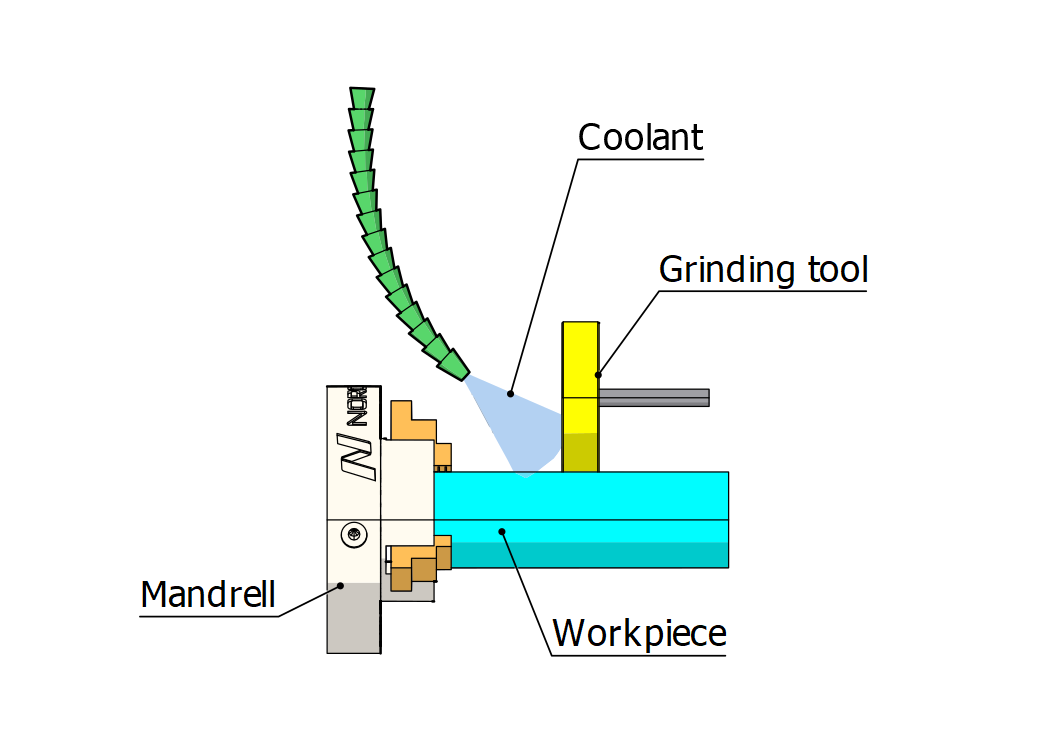

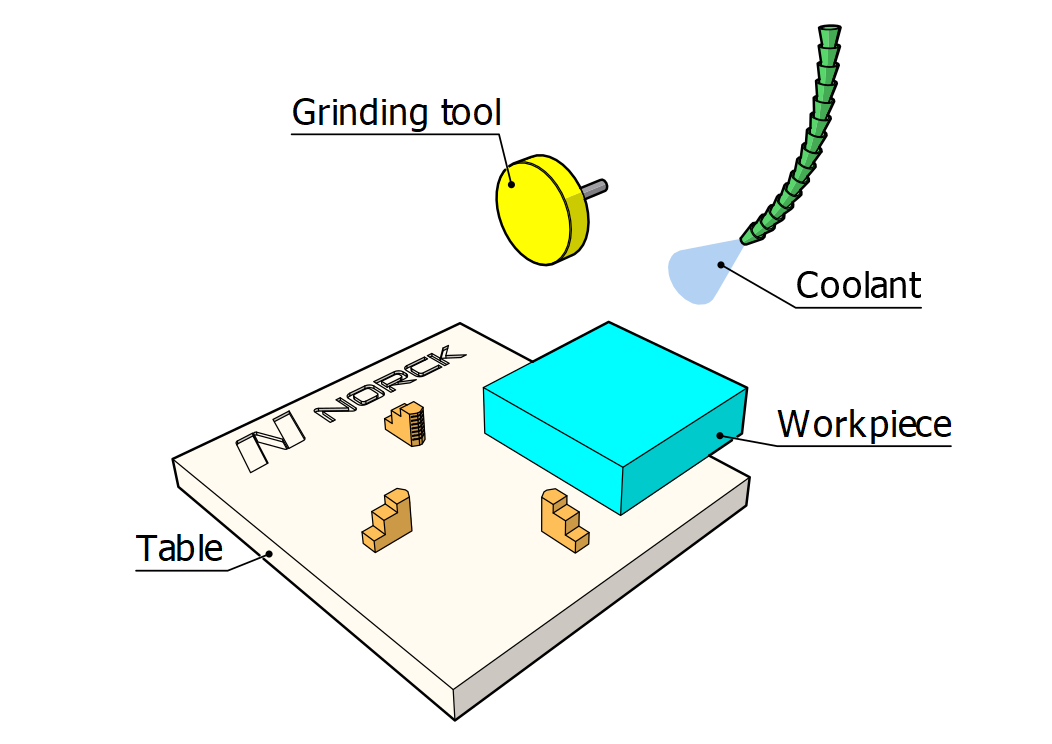

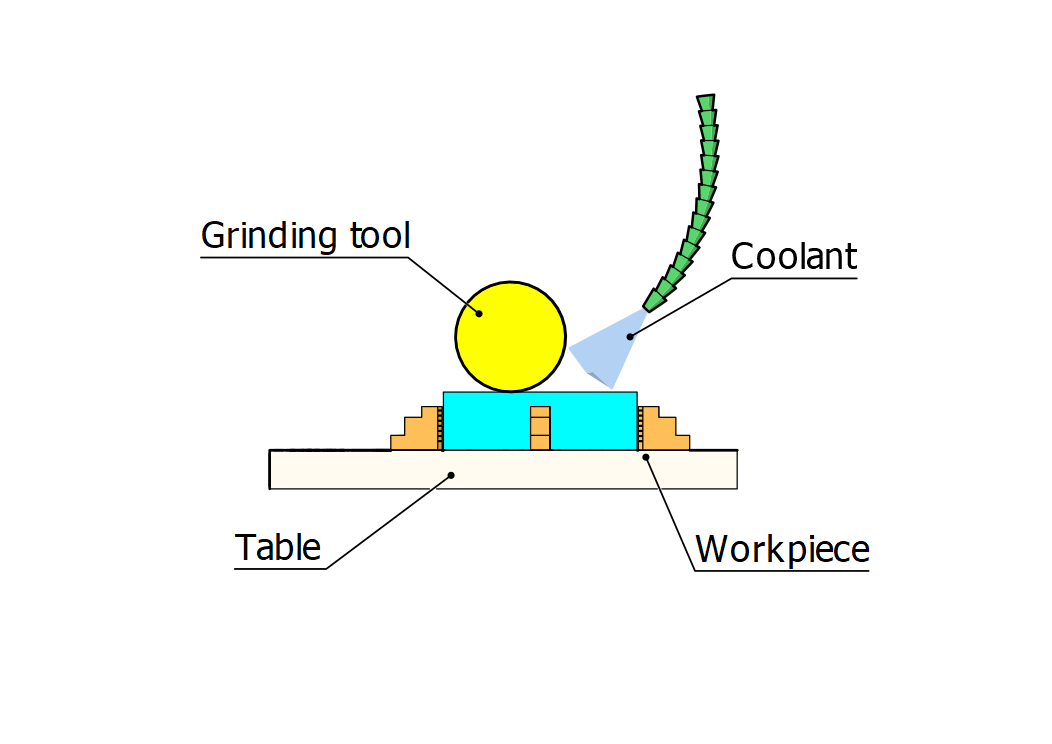

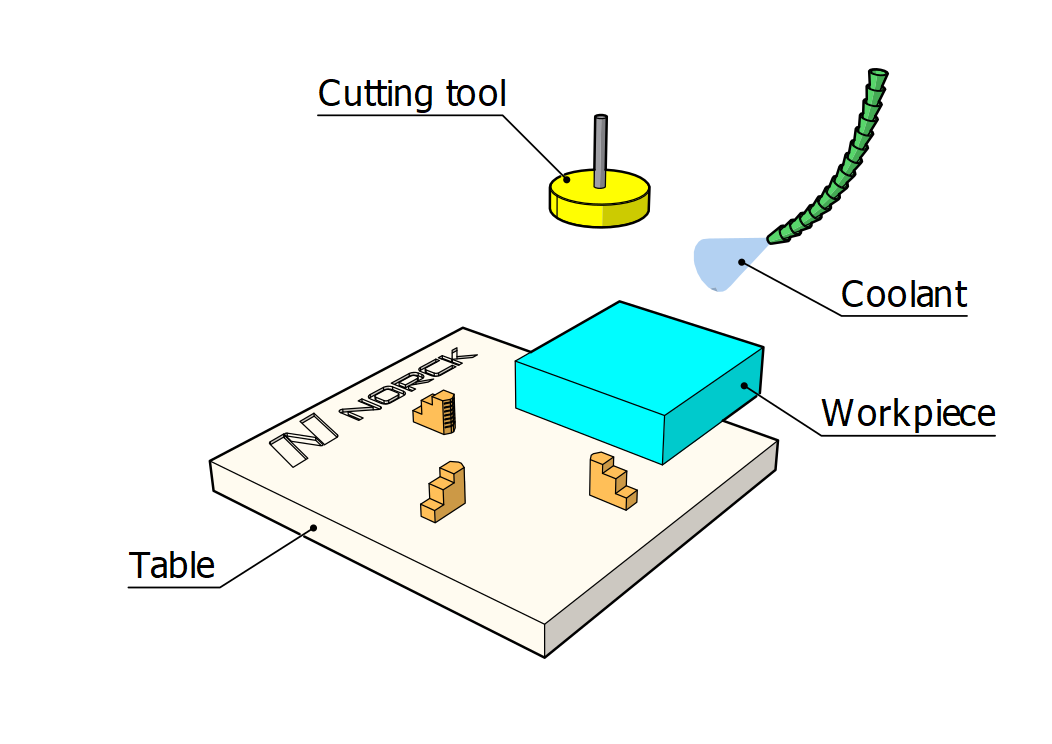

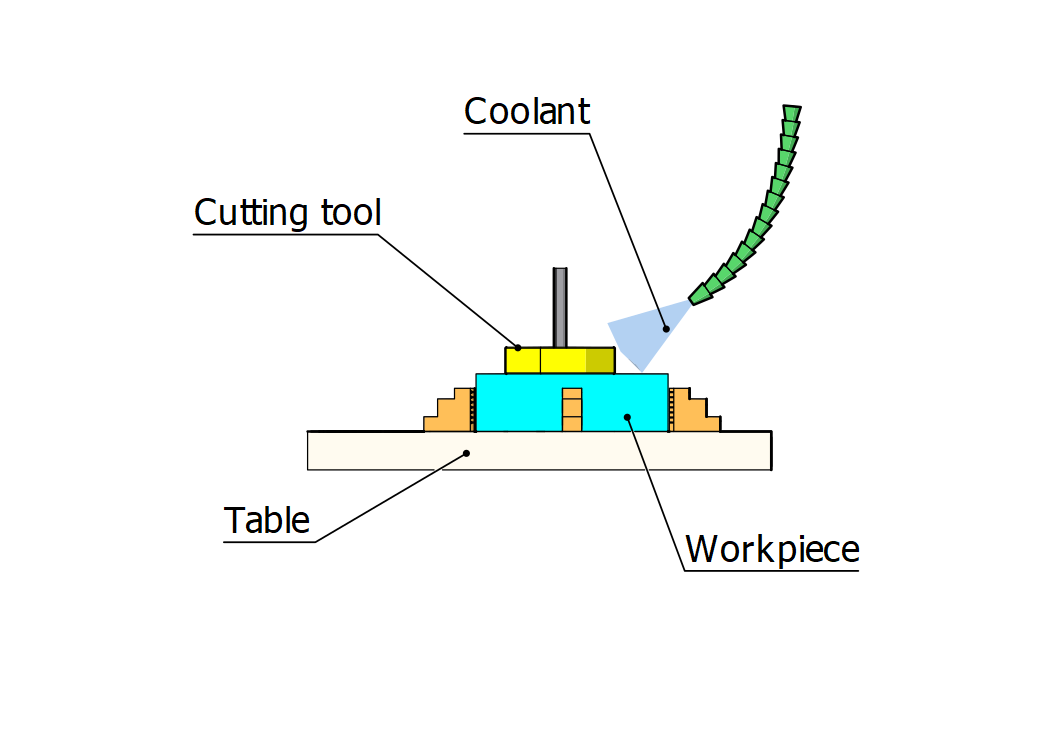

2. Surface grinding : Surface grinding is used for flat surfaces. The spindle can be mounted horizontally for plane grinding or vertically for grind deburring

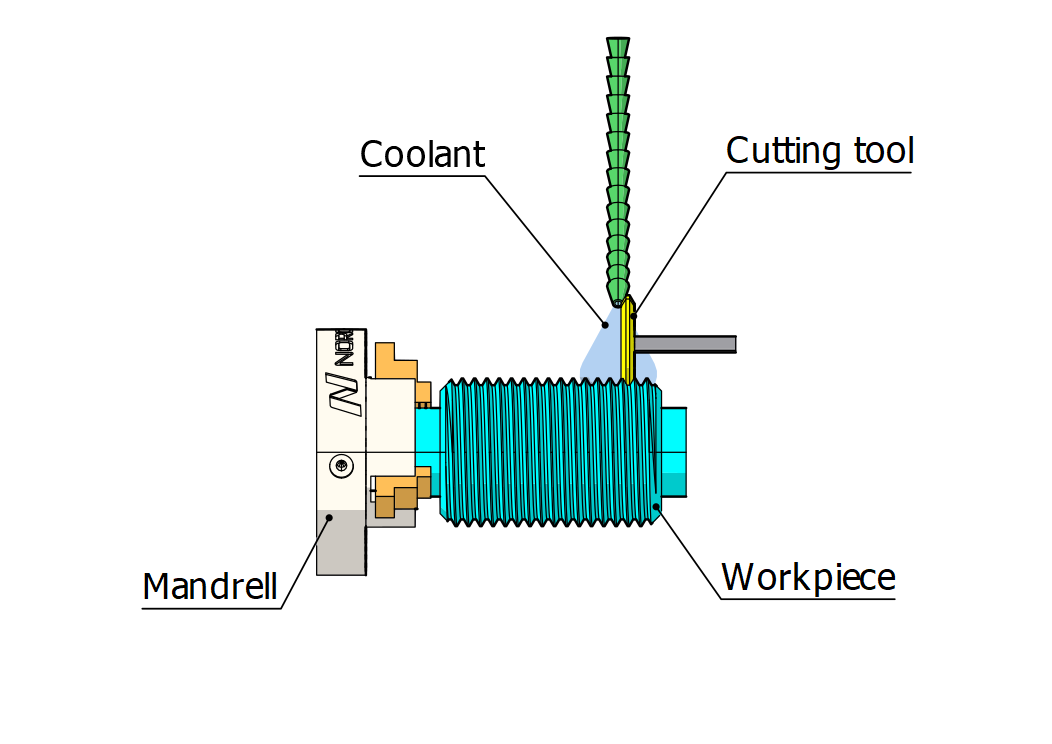

3. Thread grinding : It is a grinding process for threads. In this process, a thin grinding wheel is used to polish

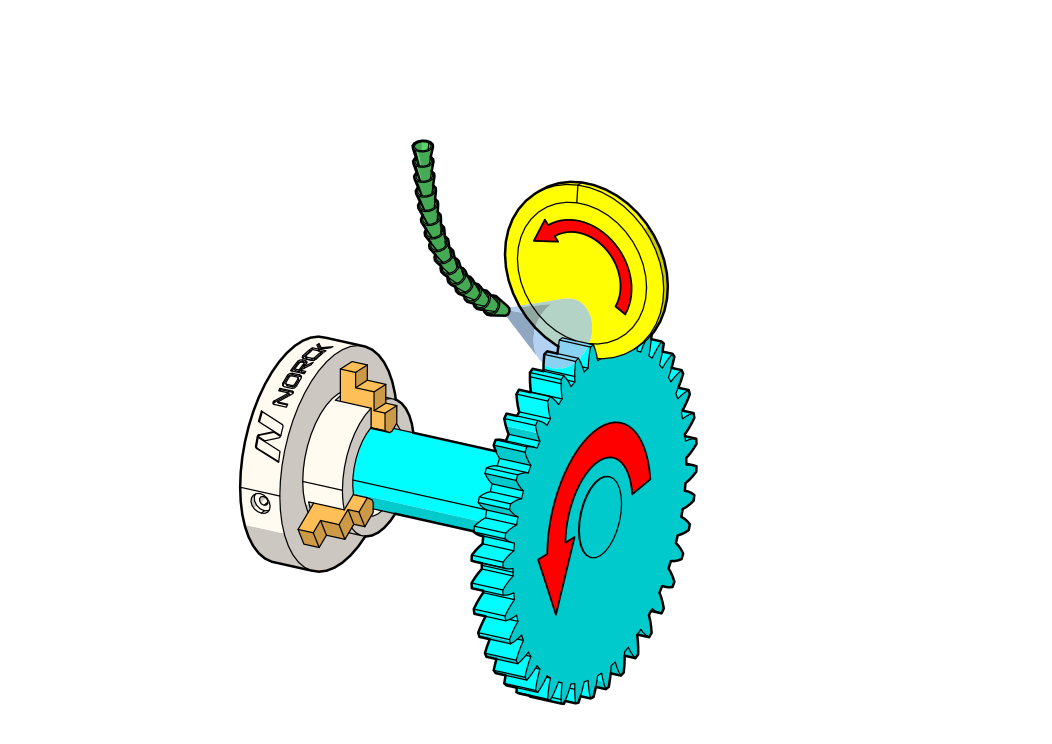

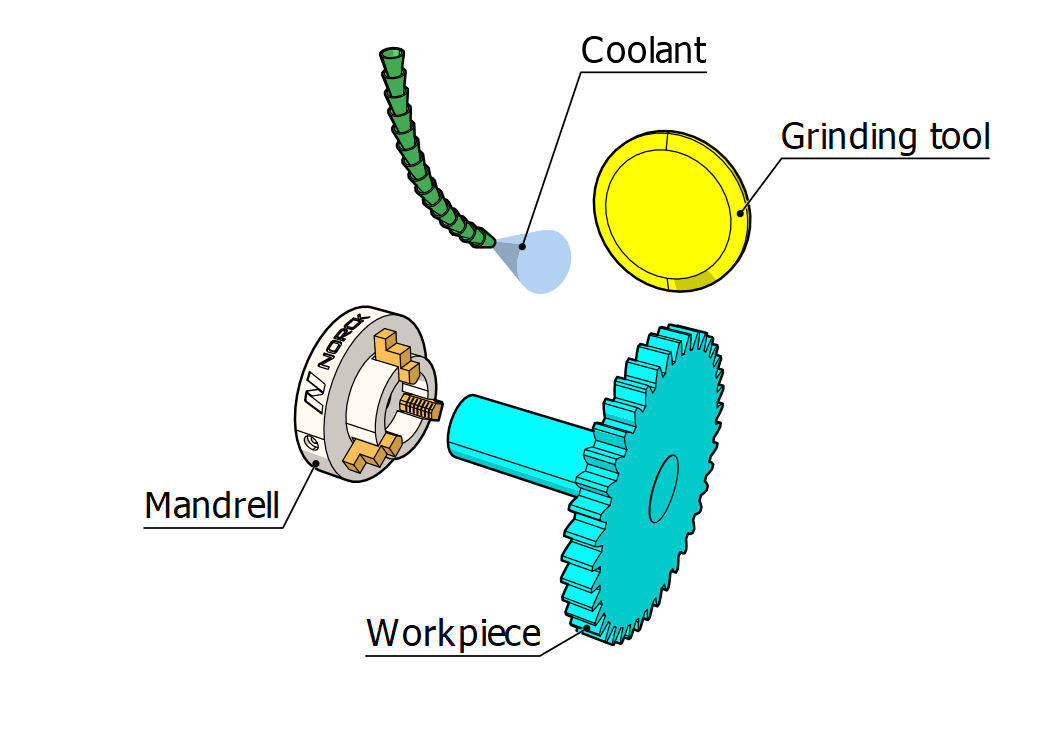

4. Gear grinding: Gear grinding is a polishing process for gears. This process is made by using a rotating thin grinding wheel to grind between gear teeth. After grinding each tooth, the gears rotate to grind the next one.

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.