Precision CNC Machining

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck: Your Partner for Precision Deep Drawn Metal Components

Norck delivers expertly manufactured deep-drawn metal parts that push the boundaries of formability. We specialize in aerospace, automotive, industrial, and other sectors where seamless components, precision tolerances, and challenging materials are required.

Capabilities for Deep Drawing Success:

Norck's Engineering Edge: It's More Than Just Forming

Why Choose Norck for Deep Drawing?

Deep drawing is forming process for sheet metal, in which a sheet metal blank is stretched to create a hollow part with a uniform wall thickness. It typically creates hollow parts, such as cylinders, boxes, and

cups.

Deep drawing can produce parts with tight tolerances and a high degree of precision, and it is well-suited for creating parts with a significant depth-to-diameter ratio.

Deep drawing parts can be used in a wide range of industries,

including:

• Construction: Bending components for construction projects such as roofing and siding

• Automotive: Bending sheet metal for use in body parts such as doors, hoods, and fenders

• Aerospace: Bending sheet metal for use in the manufacturing of fuselage, doors, and fenders

• Advertising: Bending sheet metal for signage and advertising, including signs and billboards

• Food processing: Bending sheet metal for beverages, kitchen equipment

• Transportation: Bending sheet metal parts for cars, trains, buses, and aircraft

• Art: Bending sheet metal for use in building cladding

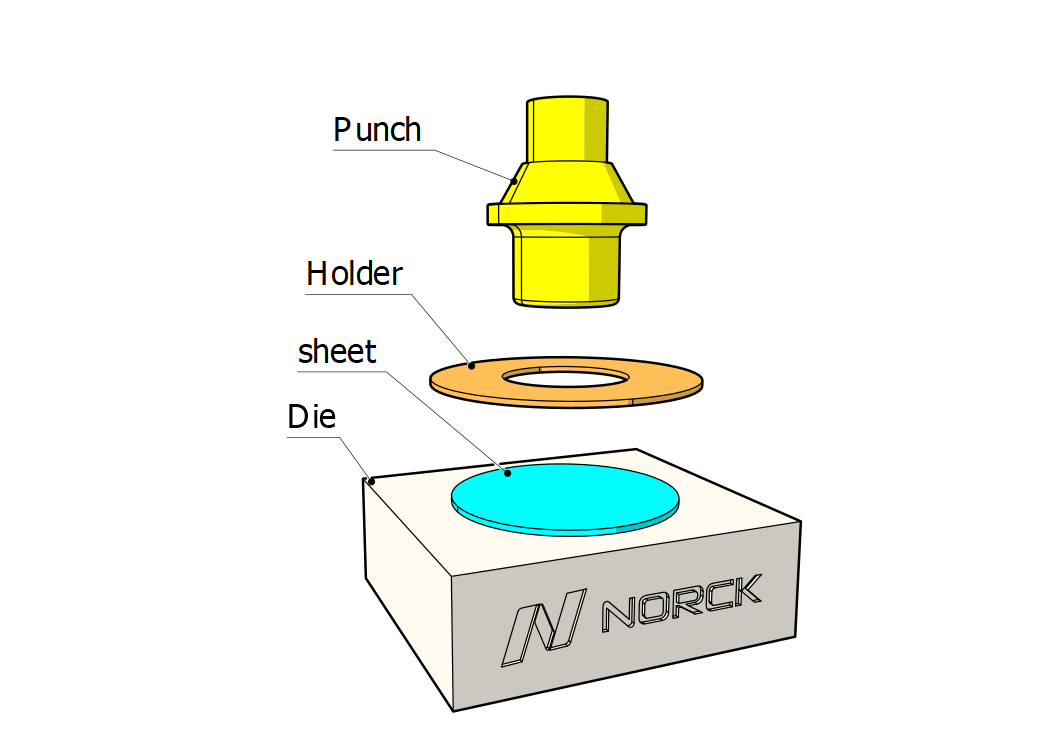

Deep drawing is a specialized process to create hollow parts with a uniform wall thickness. The process typically involves a stamping press, a specialized die, and a punch. The steps and equipment used may vary depending on the material type, the sheet metal size, the desired shapes, and the production volume. The process may require a progressive die, a series of die stations that perform different stages of the deep drawing operation.

• Blank preparation: It involves cutting the sheet metal to the correct blank’s size and shape. It might also require lubricating and stretching the blank over a punch to ensure the metal is aligned correctly and does not wrinkle or crack during the drawing process.

• Drawing: After cutting the blank, it is placed in the die, and the die presses into the die. This process forms the blank into the desired shape. Drawing is done in one stroke, which allows for a high degree of precision and consistency.

• Trimming: The deep drawing operation leaves the workpiece with an excess of material. The trimming operation removes burrs and sharp angles and ensures the part has the correct dimensions. After the trimming, the part may undergo additional finishing processes such as painting, plating, or anodizing.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.