Precision CNC Machining

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck: Precision CNC Machining for Custom Parts and Components

Norck delivers rapid, high-quality CNC machining services tailored to demanding applications across aerospace, defense, robotics, industrial, automotive, electronics, energy, hardware, and consumer products. Our expert engineers, machinists, advanced equipment, and rigorous quality control ensure exceptional accuracy, tight tolerances, and superior part quality.

Capabilities:

Why Norck for CNC Machining?

CNC machining (Computer Numerical Controlled machining) designates a process that uses a computer to control the trajectory of the machining tool. It employs many machining techniques, such as milling, drilling, and cutting. Even 3D printing is a CNC machine.

The most common CNC machines can control the movement of the tool in 3 axes, hence the name 3-axis machining. In addition to controlling the tool, some CNC machines also control the workpiece by rotating it around its axis (4-Axis machine) or two axes (5-axis machine).

CNC machining offers more advantages over traditional machining methods:

• More accuracy: CNC machining offers tight tolerances, around ±0.0002mm

• Consistency: Since a computer executes the process, it minimizes human error.

• Faster fabrication: The fabrication process time is cut short because of the use of a computer to control the process.

• Lower production costs : The production cost is reduced because the operator has fewer interventions for controlling the tool’s trajectory and changes.

• Safer : The CNC machine has no access to the workpiece and tools when cutting the part.

There are two types of CNC machining:

1. Subtractive: By subtracting layers of material from the workpiece.

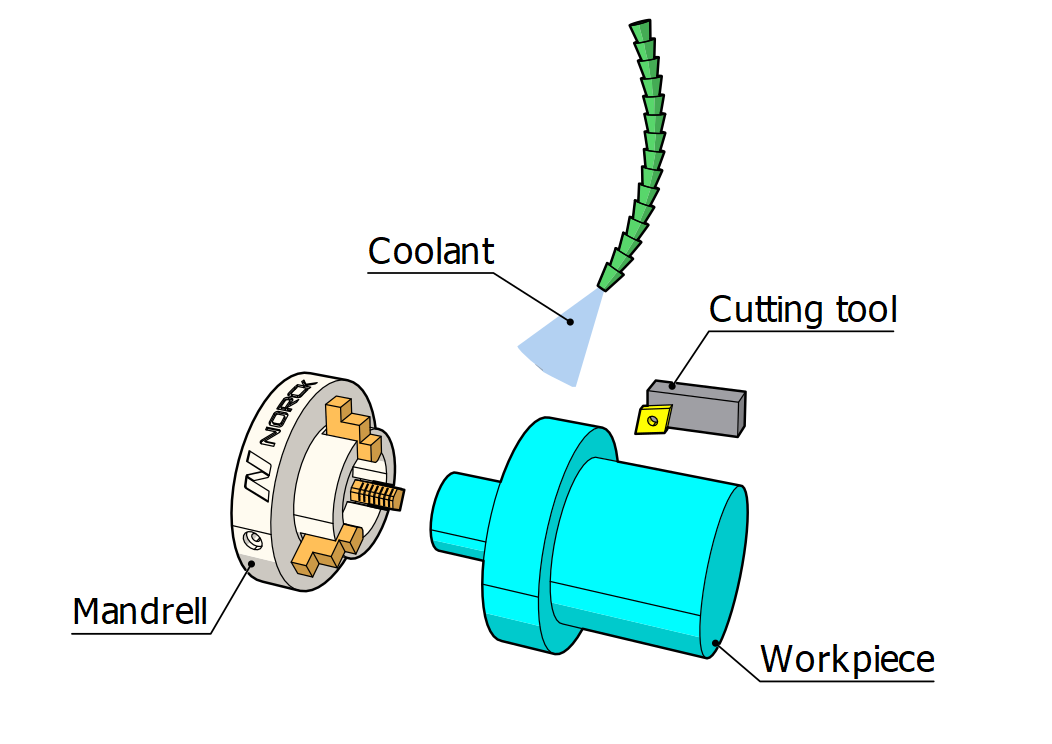

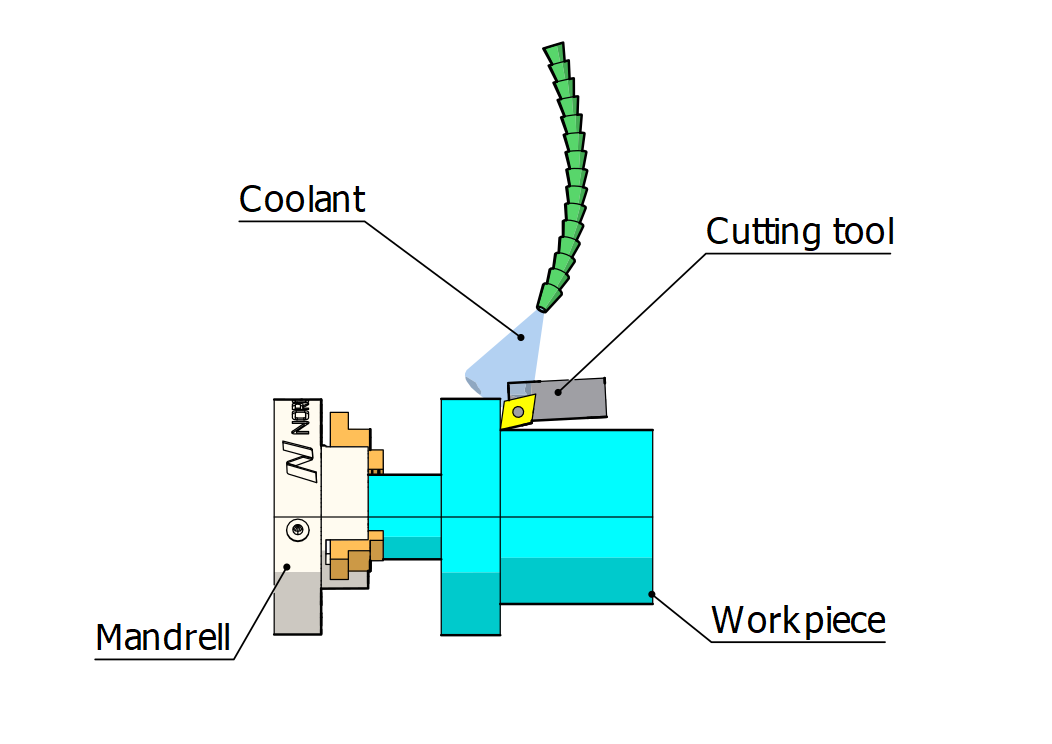

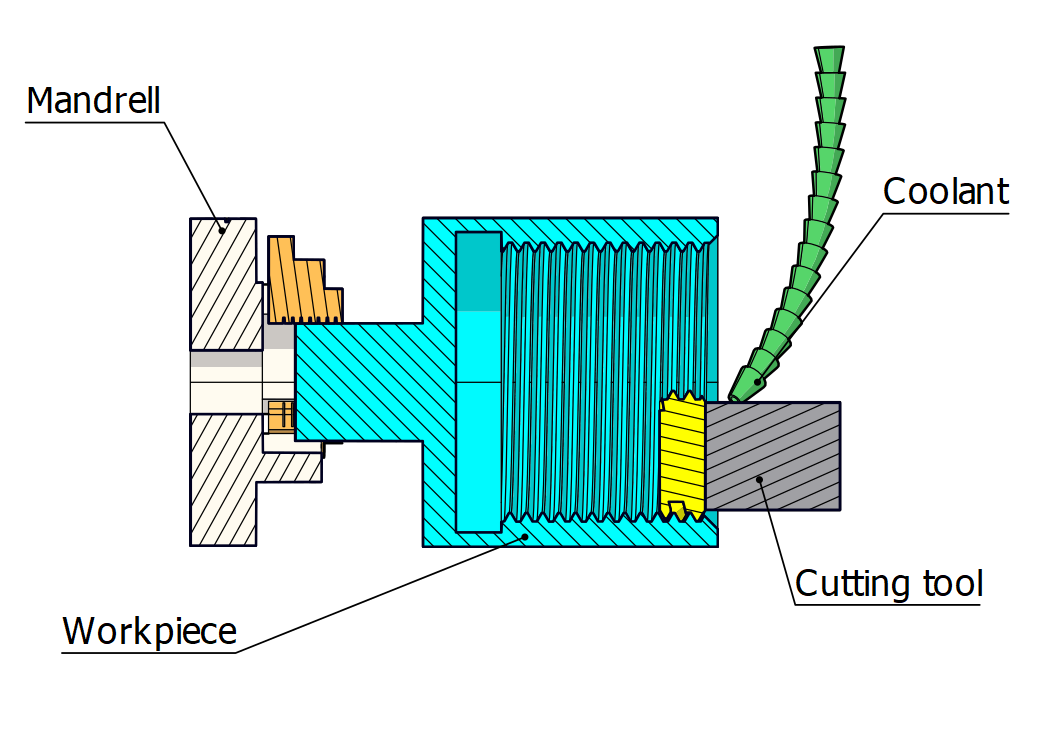

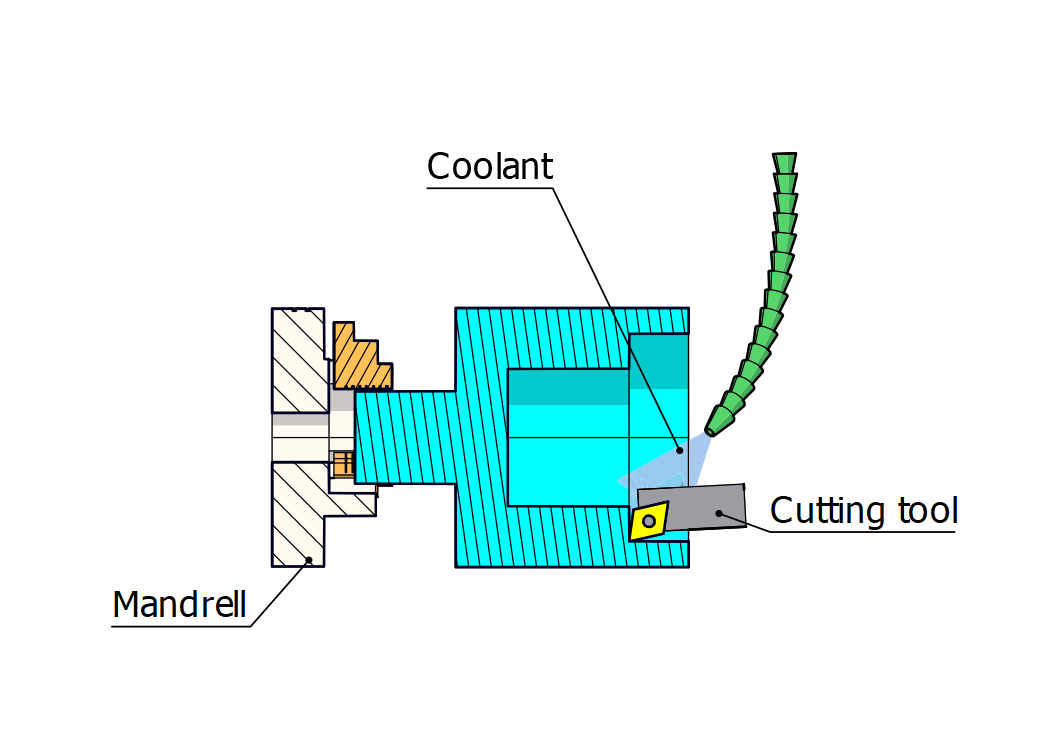

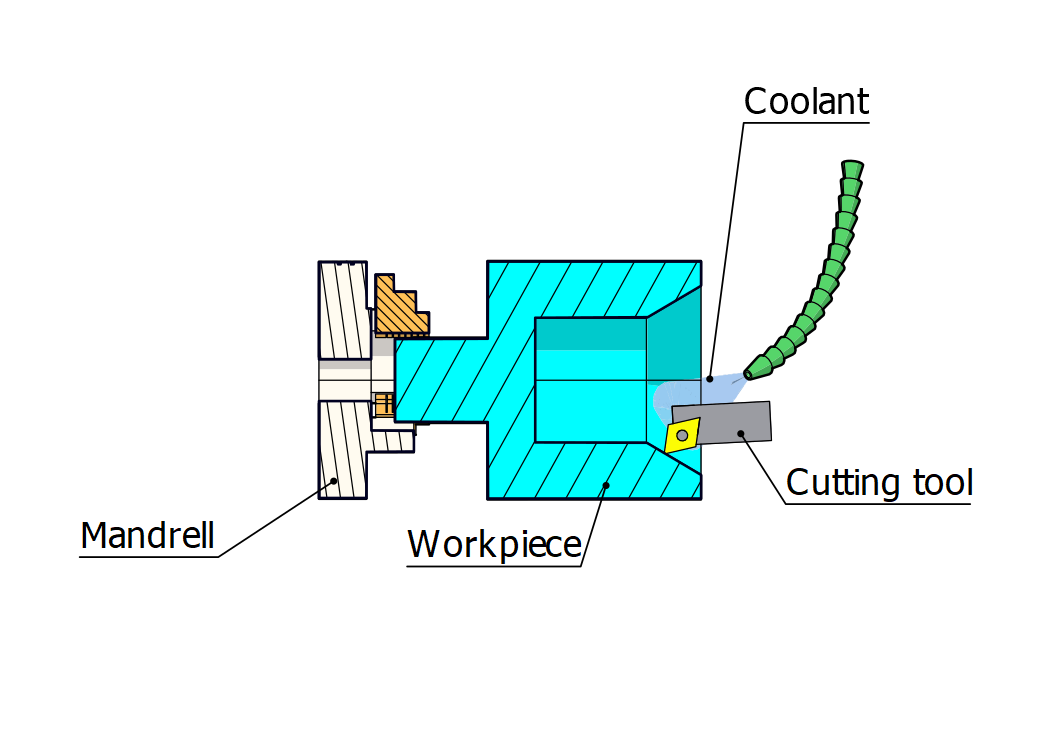

• Turning: This method uses a lathe to turn workpieces at high speeds and a tool with a special shape to remove layers of material from the workpiece. The workpiece shape is generally rounded. If the workpiece is long enough, an extra part is used to support the weight of the workpiece.

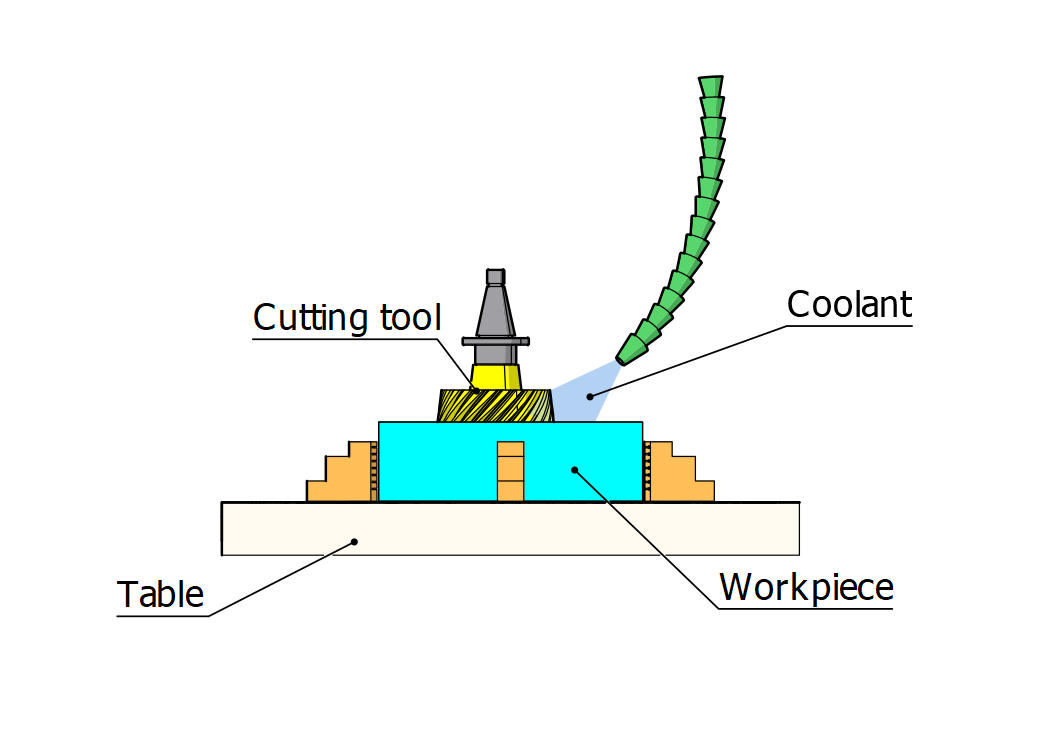

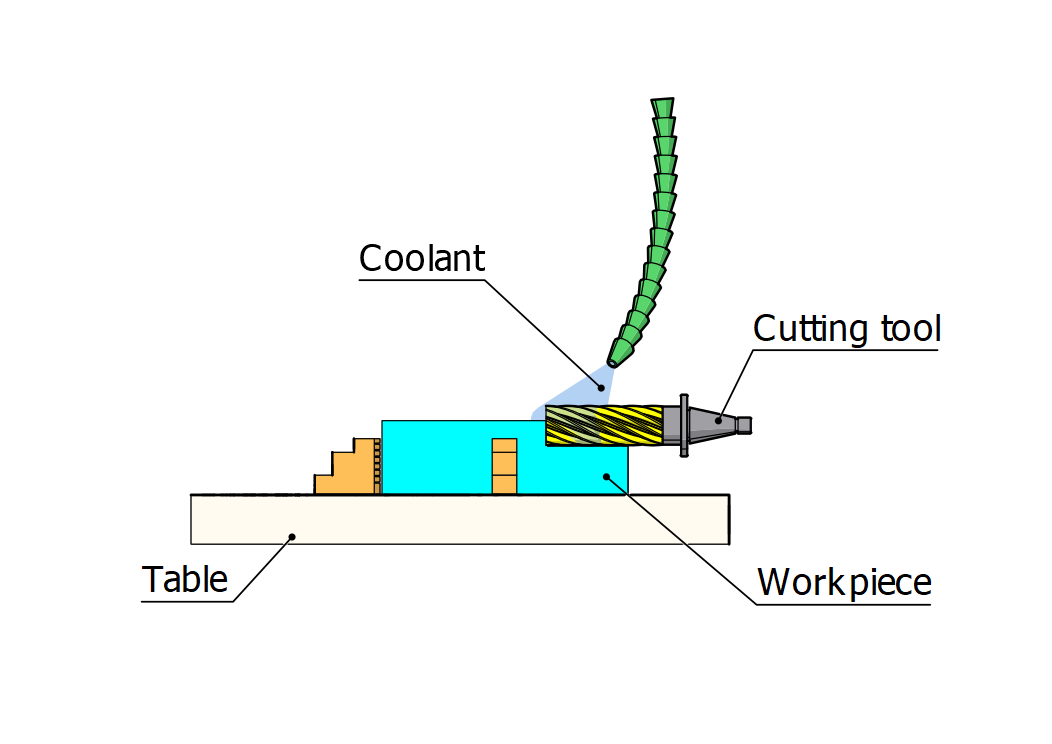

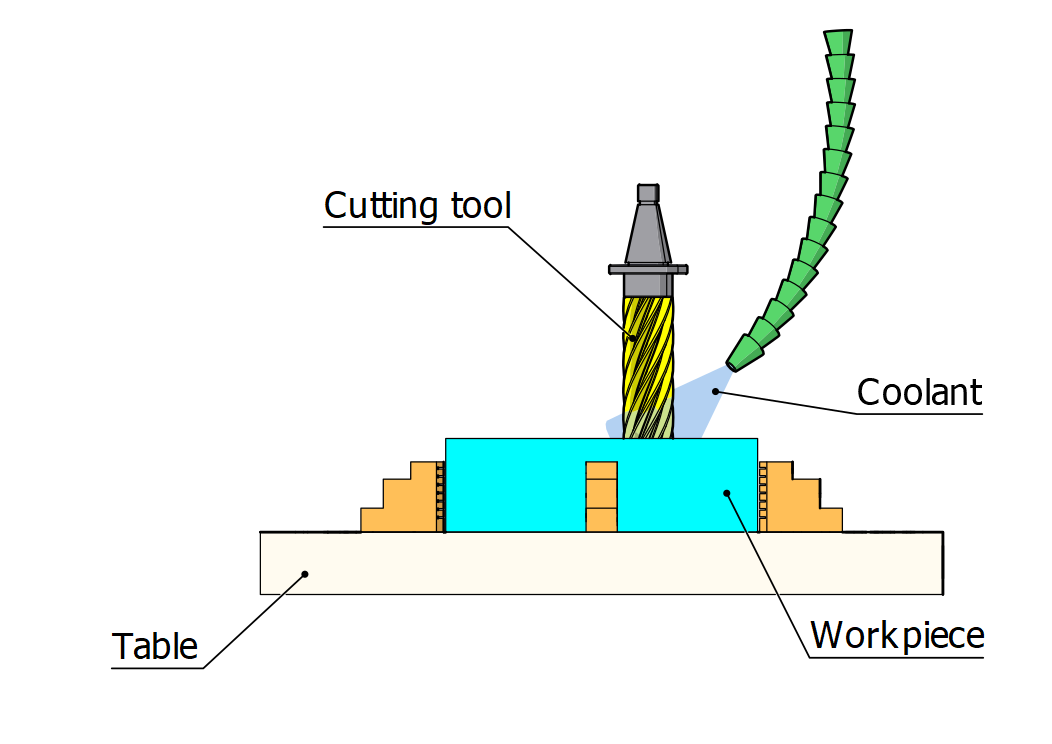

• Milling: Milling is a process that uses a rotating tool to remove material from the fixed workpiece. There are two types of milling, horizontal and vertical milling, and sometimes a 3rd type is added to the list: end milling.

• Drilling: Drilling is the process of making holes in the workpiece. The holes are generally perpendicular to the surface but can have angles with special tooling. This process includes taping, counterboring, and countersinking.

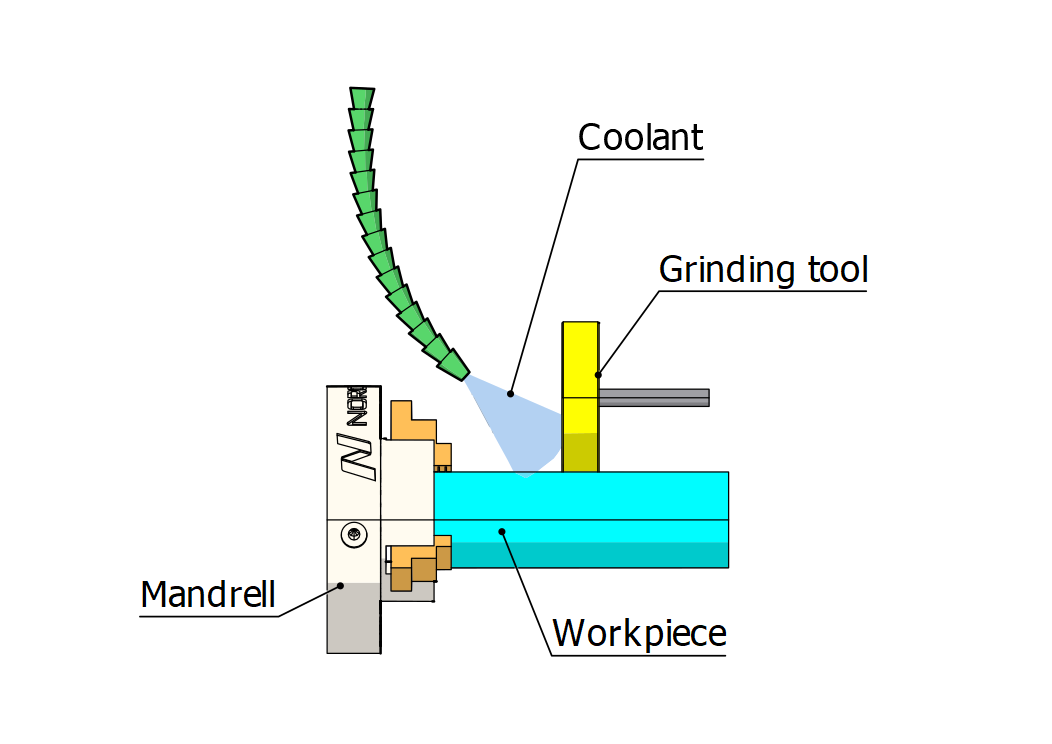

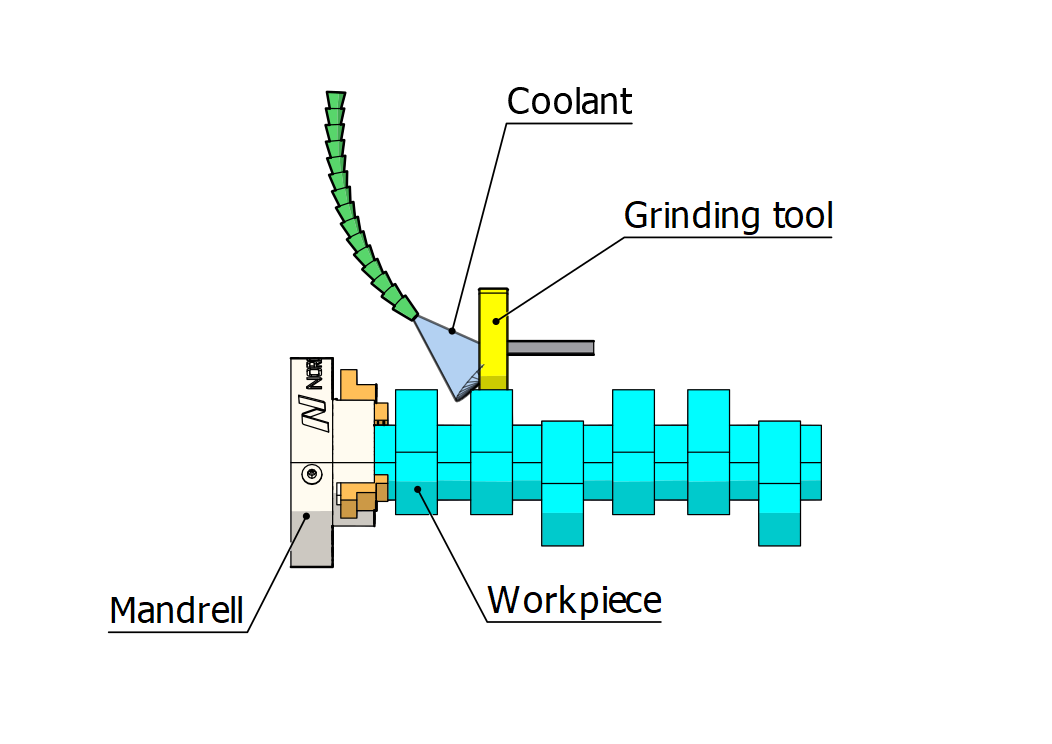

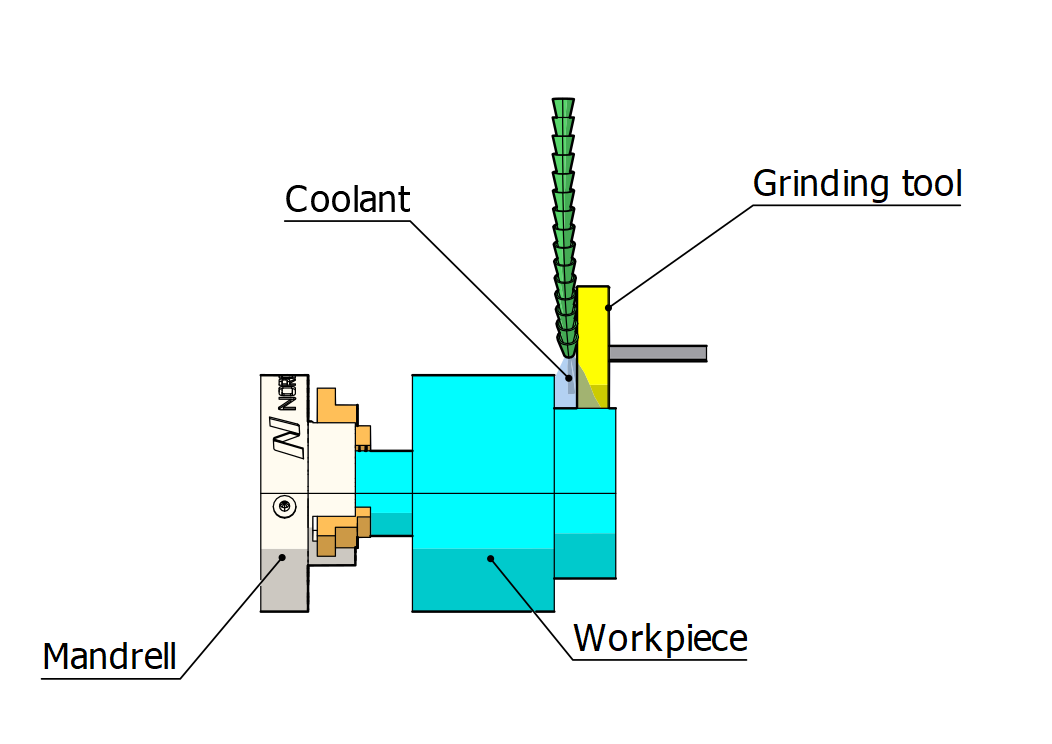

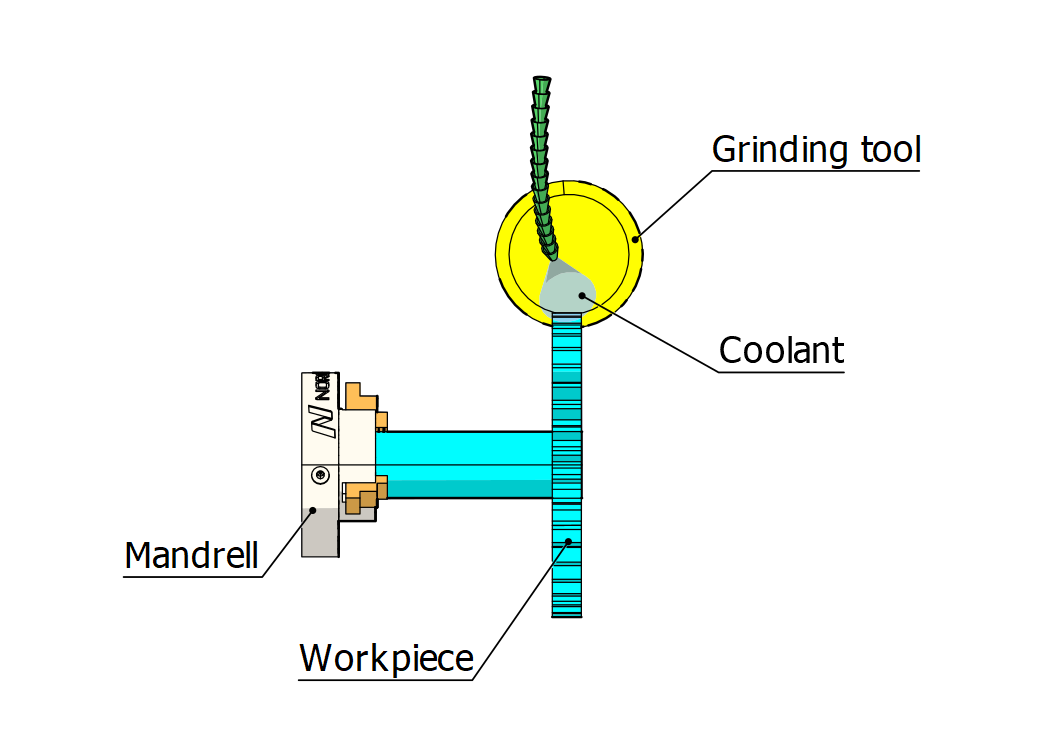

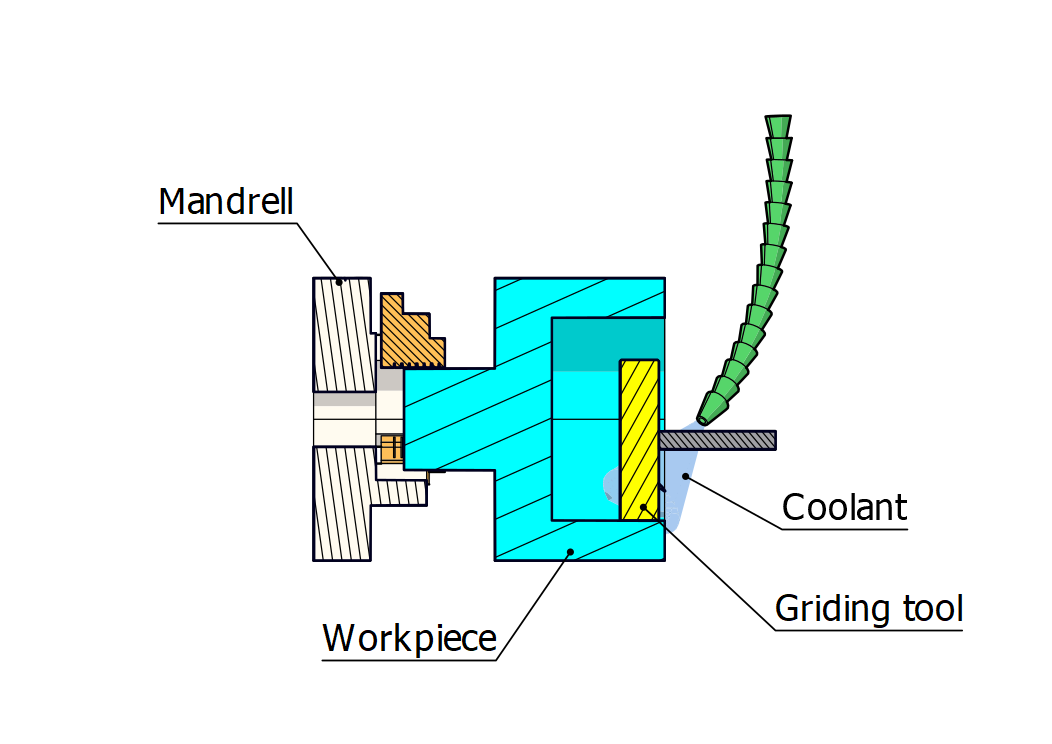

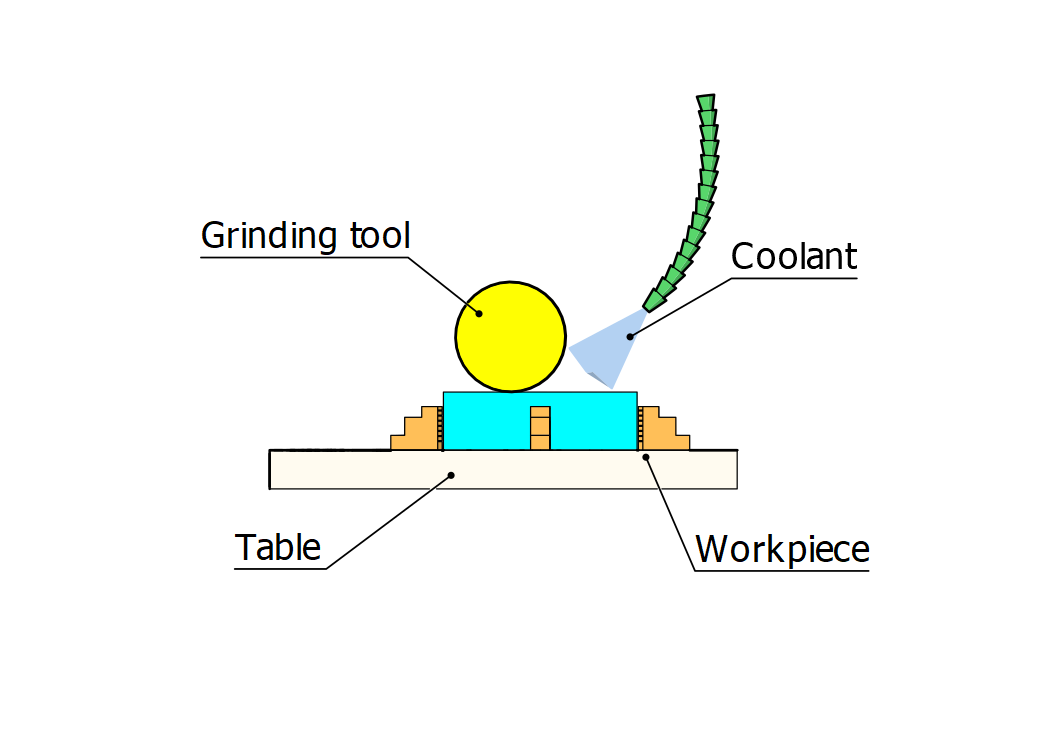

• Grinding: CNC grinding (computer numerical controlled) designates a process where an abrasive wheel refines a workpiece by removing small amounts of material. Grinding is made after machining to remove micro inches.

• Sinker and Wire EDM (Electrical discharge machining):

In the Sinker EDM, the workpiece is put into a tank and submerged in a deionized or dielectric fluid to prevent tool wear. The EDM machine uses electrical discharges between a forming tool and the working piece, as the discharges (sparks) remove material where the forming tool meets the working piece.

In the Wire EDM is a thermal cutting process of metal parts using a high voltage electrical discharge, hence the name wire EDM (Electrical discharge machining). In this technique, electrical discharges (sparks) heat a thin metal wire that cuts through the metallic part. It can cut different shapes into the tube, such as holes, letters, and complex shapes.

• Waterjet Cutting: It uses high-pressure water, generally with abrasive particles, to cut through various materials such as metals, plastics, and stones.

• Laser cutting: A process that uses a focused laser beam to cut sheet metal. The term laser stands for light amplification. It is widely used, from art and custom-made tools to aeronautic and automotive industries.

• Plasma cutting: Plasma cutting is a process that jets gas at high temperatures to cut through electrically conductive materials. Plasma can cut steel, stainless steel, aluminum, brass, and copper. It is widely used, from art and custom-made tools to aeronautic and automotive industries.

2. Additive: By forming a base material into the desired shape.

3D printing: It is a process where a liquid or semi-liquid material is deposited as layers until it solidifies and forms the desired shape. It is widely used in rapid prototyping.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.