Precision Component Manufacturing with CNC Machining

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

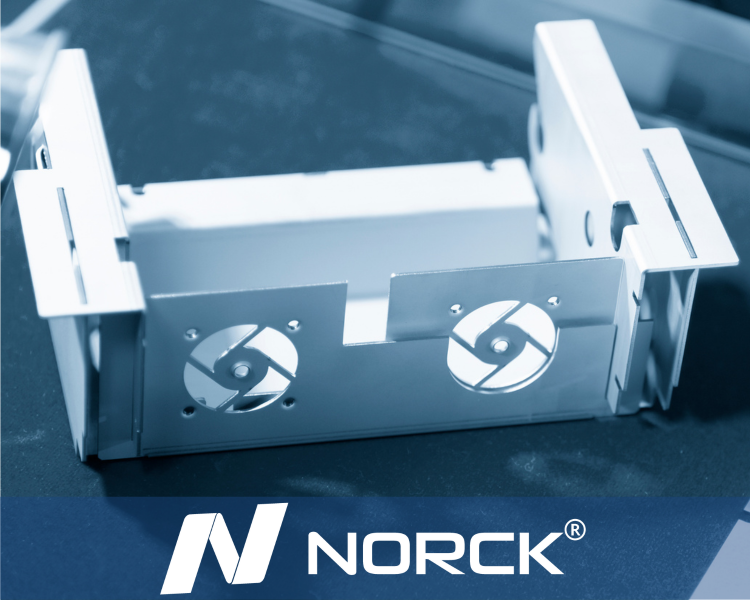

Norck: Your Partner for Streamlined Assembly Solutions

Norck delivers expert assembly services, empowering manufacturers across diverse industries to bring their products to life. We focus on precision, quality control, and scalability to help you meet market demands efficiently.

Capabilities for Assembly Excellence:

Norck's Engineering Edge: It's About More Than Just Putting Things Together

Why Choose Norck for Assembly Services?

Product assembly is critical to the success of a product. It designates assembling the fabricated parts to form a final product or sub-assemblies. It can be performed manually using conventional tools or semi-automatically using special machines (with actuators and motors).

If the product is complex, it is broken down into several operations to facilitate its manufacturing and validation. Our engineers will determine the optimal assembly line for your product.

The main benefits of using Norck Assembly services are :

- High-quality products: Our engineers will ensure that every part fits correctly, from fabrication to assembly, using Design for Manufacturing and Assembly methods (DFMA).

- Reducing production costs: By outsourcing the assembly and manufacturing, no need for extra tooling and labor work.

- Ideal for startups and small businesses: You can benefit from overspending on toolings and labor costs.

- End-to-end: Norck will be charged throughout the process from start to finish and delivers fully functional products.

The first step is to have the technical specifications of the desired product. Next, our engineers will develop 3D models and communicate them for approval. Once approved, Norck will start the manufacturing process.

After receiving the manufactured components, metrologists will inspect them for conformability to the design specifications. Technicians assemble parts manually or using semi-automatic (special machines), and the product passes through specific tests to check if it meets the specifications set by the client.

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.