Precision Component Manufacturing with CNC Machining

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Norck: Advanced Carbon DLS 3D Printing for High-Performance Applications

Norck delivers precision Carbon DLS 3D printing and a comprehensive range of additive manufacturing solutions for demanding industries – including aerospace, defense, robotics, industrial, automotive, electronics, energy, hardware, and consumer products. Our team of expert engineers and cutting-edge facilities ensure exceptional part quality, rapid turnaround, and competitive pricing.

Capabilities:

Why Norck?

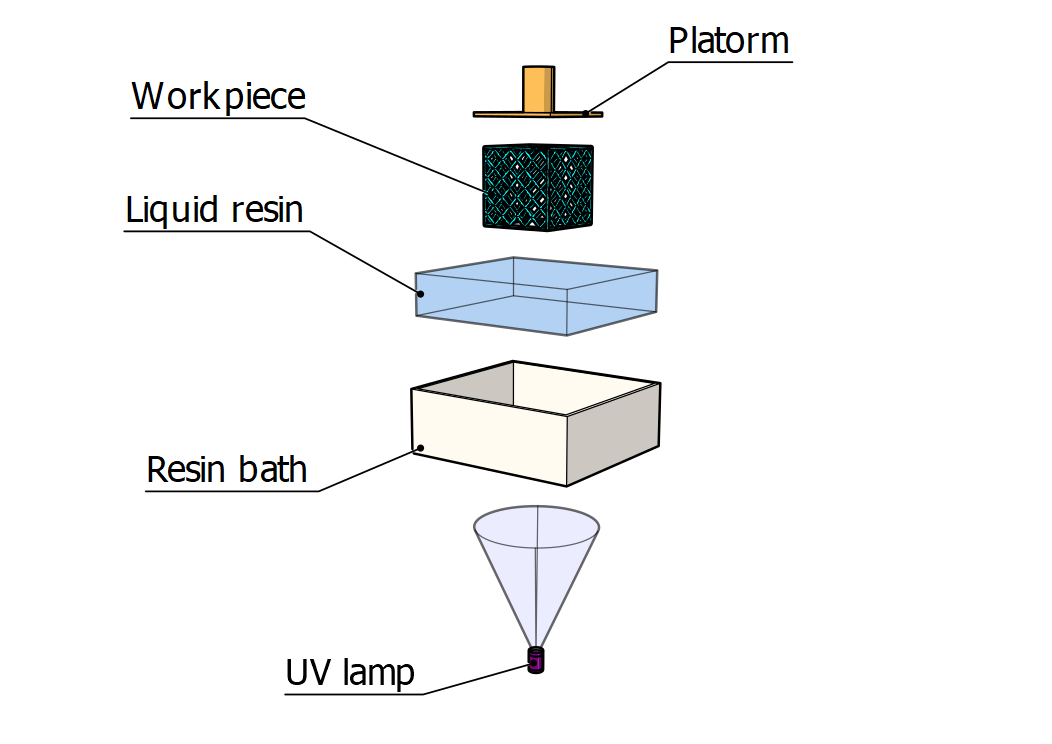

Carbon Digital Light Synthesis is an additive manufacturing process that uses a UV-sensitive resin to produce the desired model. In this process, a light source is used to project UV cross sections of a 3D model on a window to solidify the resin. It helps turn designs into scaled prototypes as close to the designed model. It is mainly used in the earliest stages of product development and can be used in conceptual models, functional prototypes, tooling, and electronics.

3D printing requires 3D CAD models to print a part or assembly. The 3D models can be made using parametric CAD software such as Solidworks and CATIA V5, or Subdivision modeling software such as 3DS and Blender.

Carbon DLS is used over other 3D printing processes due to:

- Smooth surface finishing

- Complex shapes are easier to print

- Isotropic

Although there are disadvantages to using Carbon DLS:

- Limited material choice

- Higher cost

The 3D printer slices the 3D model into several cross sections. A light source is used to project UV cross sections of a 3D model on an oxygen-permeable window to solidify the resin. UV light is used to harden the projected layer. Oxygen helps keep a thin uncured resin at the bottom of the printed model. This layer is called the “Dead Zone.” When a whole layer of the desired shape is deposited, the platform moves up to process the next layer. The printed part is heated to improve its mechanical characteristics.

Once the 3D printed model is finished, it can be removed from the platform. Post-processing might be required to remove any excess material and burrs or to smooth surfaces.

- Most used materials:

• Elastomeric resin

• Flexible resin

• Rigid resin

• Silicone

• Cyanate ester

• Urethane Methacrylate

• Epoxy

• Medical ABS-like

Parts and assemblies should follow specific design rules to be printed correctly. Norck offers engineering services that will help you confirm your design for 3D printing.

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.