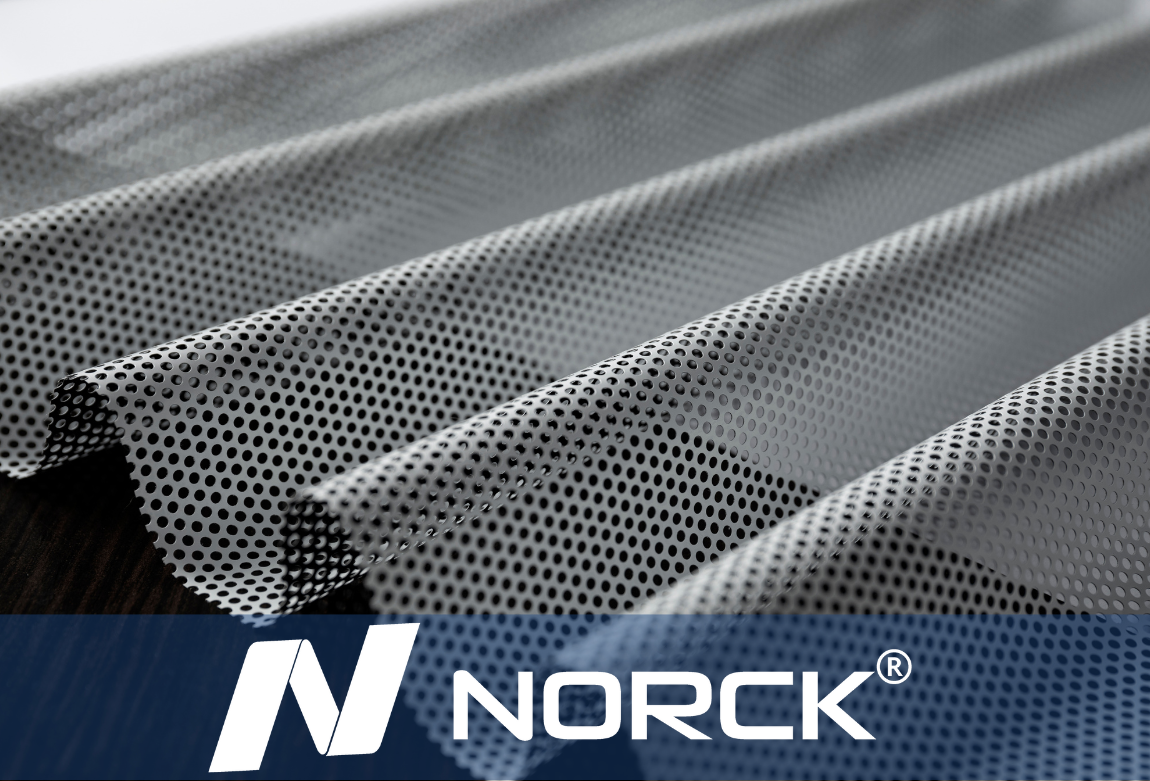

Sheet Metal Fabrication and Norck’s capabilities

Sheet metal fabrication is a versatile process that involves cutting, bending, and assembling metal sheets to create various products. It is used in industries ranging from automotive to aerospace, showcasing its importance in manufacturing.

As a leading expert in sheet metal fabrication, Norck offers unmatched capabilities that set them apart from the competition. With state-of-the-art technology and a team of skilled professionals, they can tackle any project with precision and efficiency. Whether you need custom parts or large-scale production runs, Norck has the expertise to deliver high-quality results every time. Trust Norck for all your sheet metal fabrication needs and experience the difference that their capabilities can make for your business.

The Importance of Quality Fabrication for Industries

In many different sectors, sheet metal fabrication is vital because it provides the necessary parts for production procedures. Good fabrication is essential because it guarantees the end goods' performance and durability. Industries rely on sheet metal work to be precise and accurate in order to meet requirements and maintain high standards.

Selecting a reliable fabrication business helps you avoid expensive delays or rework by ensuring that the finished product will meet industry requirements. Superior fabrication also improves production lines' overall effectiveness, which raises output and profitability.

For goods to be dependable and long-lasting, high-quality fabrication is a must in all industries, including electronics, aerospace, and automotive. Every aspect counts to ensure that the created components function as best they can under a variety of circumstances, whether they are custom parts or large-scale projects.

In an industrial landscape that is constantly changing, successful outcomes in various sectors continue to depend on high-quality sheet metal production. It takes more than merely cutting and bending metal to produce work of excellence that both meets and surpasses industry standards.

Get a Quote

Norck: A Leading Provider of Sheet Metal Fabrication Services

Norck has established itself as a dominant entity in the domain of sheet metal fabrication services, garnering a notable standing due to its steadfast dedication to excellence and accuracy. Norck has established itself as a reliable partner for customers looking for top-notch sheet metal solutions because of its heritage in craftsmanship.

Modern facilities with state-of-the-art equipment that raises the bar for sheet metal manufacturing are the foundation of Norck's success. The ability of the organization to turn plain metal sheets into complex parts demonstrates its commitment to accuracy and high standards. This dedication is shown in the range of industries where Norck is a dependable supplier meeting a wide range of customer requirements.

A further testament to Norck's expertise in the sheet metal fabrication industry is the company's ability to incorporate cutting-edge technologies into its operations smoothly. The organization's proactive strategy guarantees that customers obtain customized solutions along with the guarantee of precision and dependability in each manufactured part.

Being the go-to source, Norck continues to influence the market and establish standards for quality in sheet metal fabrication services. Customers rely on Norck to provide excellent solutions, which makes it a top option for manufacturers who value accuracy and high standards

The Process of Sheet Metal Fabrication at Norck

Norck's sheet metal fabrication process is a prime example of how to seamlessly blend state-of-the-art technology with precision to deliver exceptional outcomes for a wide range of applications. The process starts with a thorough design phase in which Norck works closely with clients to comprehend their particular requirements.

Through the use of sophisticated Computer-Aided Manufacturing (CAM) and Computer-Aided Design (CAD) technologies, the designs are converted into comprehensive blueprints that direct the fabrication process.

Following the design stage, Norck uses cutting-edge equipment, such as Computer Numerical Control (CNC) systems, to perform precise bending, shaping, and cutting of raw metal sheets. Throughout the fabrication process, this technological integration guarantees a high degree of quality, uniformity, and efficiency. A key component of Norck's technique is their proficiency in the selection and handling of materials, whether they are working with steel, aluminum, or other alloys.

The early phases of shaping are followed by welding and assembly, which are completed with exceptional craftsmanship to join the numerous components smoothly. This process is essential in order to guarantee the final product's longevity and structural integrity. Norck uses sophisticated inspection equipment, such as coordinate measuring machines and laser scanning, to ensure the highest quality (CMM).

With the aid of these instruments, exact measurements and comprehensive inspections are made possible, which is consistent with Norck's dedication to providing sheet metal products that meet the highest quality requirements.

The final steps of the production process include adding finishing touches that improve functionality and appearance. Norck makes sure that the fabricated components not only satisfy technical criteria but also have a polished and professional appearance, whether it be by coating, polishing, or other surface treatments.

Throughout the whole process of fabricating sheet metal, Norck is committed to personalization. Norck guarantees that the finished goods properly match the intended application by customizing solutions to satisfy unique client demands. Prototyping is prioritized in addition to customization, enabling clients to confirm designs prior to large-scale production.

Norck's Advanced Capabilities in Sheet Metal Fabrication

Norck has made a name for itself as a forerunner in the complex field of sheet metal manufacturing, where technological refinement and precision are critical. The company, which is well-known for its dedication to quality, has made large investments in modern facilities and cutting-edge equipment, creating new standards in the sheet metal fabrication industry.

State-of-the-Art Facilities

Modern facilities are the foundation of Norck's excellence. These facilities, which are outfitted with state-of-the-art machinery and cutting-edge technology, provide the foundation for Norck's capacity to provide excellent sheet metal solutions.

Investing in contemporary infrastructure broadens Norck's capabilities and improves the manufacturing process efficiency, enabling the company to take on projects of various complexity across industries.

CNC System Integration

Norck is a leader in sheet metal manufacturing because it incorporates Computer Numerical Control (CNC) technology into its processes with ease. The production process is more accurate and efficient when CNC technology is used. Intricate designs and close tolerances are consistently accomplished by Norck thanks to computer-controlled machinery that cuts, shapes, and forms metal sheets with unmatched accuracy.

This integration not only establishes a new benchmark for accuracy but also establishes Norck as a pioneer in the application of cutting-edge technologies to sheet metal manufacturing.

CAD/CAM Integration

Computer-Aided Manufacturing (CAM) and Computer-Aided Design (CAD) technologies are seamlessly integrated by Norck, further demonstrating its dedication to cutting-edge capabilities. By guaranteeing accurate translation of design criteria into the production phase, this integration improves the entire fabrication process.

The combined power of CAD and CAM enables increased precision, speed, and adaptability to a wide range of design specifications. Because of Norck's expertise with CAD/CAM integration, the production process is streamlined and complicated; bespoke designs may be realized, satisfying the specific needs of customers in a variety of industries.

Material Expertise

Norck's extensive understanding of a wide range of materials used in sheet metal manufacturing is only one example of its sophisticated skills. With accuracy and strategic vision, the company's team of professionals navigates the special qualities of materials, including copper, brass, aluminum, and steel.

Norck can customize its fabrication techniques to fit the unique needs of various industries thanks to its material knowledge. The adaptability of aluminum for aerospace applications or the strength of steel for structural components—or both—Norck's advanced capabilities are best demonstrated by its ability to work with a variety of materials.

Customization and Prototyping

Norck stands out in the field of sheet metal manufacturing because of its focus on customization and prototyping. The business is aware of how critical prototyping is to validate designs before large-scale production. Because Norck's prototyping services guarantee that the finished product precisely matches the client's vision, they not only save time and resources but also contribute to the overall success of projects.

Furthermore, Norck is excellent at customization, providing specialized solutions to match the unique requirements of every customer. This degree of adaptability and flexibility demonstrates even more how advanced Norck is at meeting a variety of needs.

Get a Quote

Benefits of Choosing Norck for Sheet Metal Fabrication Needs

Modern production relies heavily on sheet metal fabrication, and choosing the best partner for your requirements can have a big impact on the process' effectiveness and quality. A prominent player in the sheet metal fabrication market, Norck provides various benefits that set it apart for customers looking for accuracy and superiority in their work.

Selecting Norck for sheet metal fabrication requirements has several benefits, chief among them being its steadfast dedication to precise artistry. The business has established a reputation for producing goods with demanding accuracy and making sure that fabricated components adhere to the strict requirements of numerous industries.

Norck uses cutting-edge technology, such as Computer Numerical Control (CNC) systems, to make complex designs and precise tolerances a reality. Because of this dedication to correctness, Norck stands out as a dependable partner for customers who value accuracy in their sheet metal components.

Norck's commitment to technological excellence is demonstrated by its investment in modern facilities furnished with state-of-the-art equipment. These state-of-the-art facilities expand the possibilities and improve the efficiency of the fabrication process.

Norck provides prototyping services that go above and beyond ordinary solutions. It guarantees that the finished goods exactly match the client's expectations by enabling clients to test and improve their designs before full-scale production.

Norck has extensive experience in sheet metal manufacturing for a variety of sectors. From electronics and technology to medical equipment, automotive, and aerospace, Norck has demonstrated its adaptability in satisfying the specific needs of many industries.

When customers are looking for sheet metal solutions for a range of applications, Norck is the firm to turn to because of its adaptability to a wide range of industry needs, which highlights the breadth of its knowledge and experience.

Conclusion

In conclusion, sheet metal fabrication is a cornerstone of modern manufacturing, and Norck's advanced capabilities elevate it to a position of prominence in the industry. The company's commitment to precision craftsmanship, state-of-the-art technology, and environmental responsibility make it a preferred choice for clients across diverse sectors. As industries continue to evolve, the role of sheet metal fabrication in shaping the future of manufacturing remains pivotal, with Norck leading the way with innovation and excellence.

English

English